Fabert – Automatic apparel control system

- Home

- Case Studies

- FABERT – Automatic apparel control system

Efficient automatic lines for high fashion apparel

LCS developed for Fabert an automatic system to check high fashion apparel. An efficient solution that ensures maximum traceability of all items to be shipped.

The Company and its Needs:

Confezioni Fabert produces women’s and men’s clothing for third parties. The company has been active in the sector for over 40 years and produces a wide range of items including T-shirts, polo shirts, shirts, dresses, sweatshirts, and jersey jackets. The company currently collaborates with some of the biggest Italian and international fashion brands and employs a highly specialized workforce to guarantee the customer a high-quality product and service.

With this in mind, Fabert’s aim was to implement an automatic system capable of checking the presence of the barcode label on garments arriving from the ironing department, counting the articles and associating them with the order being processed.

These activities were carried out entirely manually, with the operators checking individual items, reading the barcodes via proper terminals and preparing the items for shipping.

LCS was therefore entrusted with the development of a solution that would make the identification and management of garments more reliable and efficient. The key was to ensure the traceability of articles and eliminate errors caused by manual handling.

The implemented solution:

The solution developed and implemented by LCS consists of 2 parallel automatic lines equipped with box loading station, conveyor system, barcode reader or RFID reading system and manual boxing station with weighing system.

The automatic system engineered by LCS operates under the guidance of the proprietary software LogiCon, in direct connection with Fabert’s ERP. LCS supervisor controls the perfect correspondence between the goods arriving from the ironing department and the items listed for shipment, ensuring maximum accuracy in the preparation of orders. Thanks to LogiCon, in fact, the customer’s ERP receives the information about the quantity of the items read through the gate, the weight of the single items and the total weight of the shipping box.

How the 2 automatic lines work

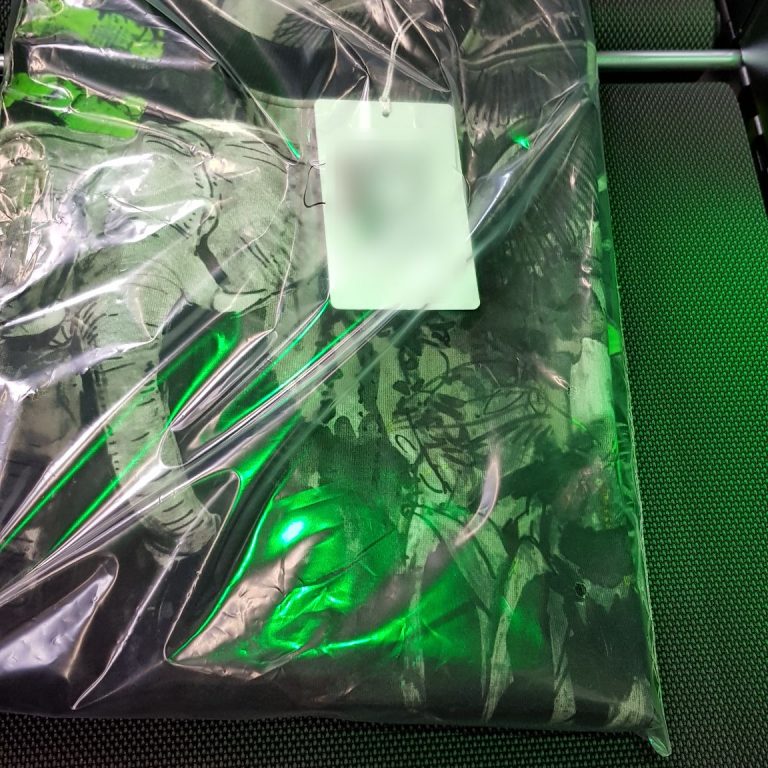

The ironed, bagged and barcoded garments arrive at the 2 automatic lines where the operator, using a PC, activates a shipping list by selecting the filters for which the material is to be checked and divided into shipping cartons (tag, season, etc.).

The items are then loaded on the conveyor belt of the first line, which automatically conveys them to the gate with barcode reading cameras, which is responsible for the identification of the individual garment. Based on the active filters, the supervisor LogiCon verifies that the read barcode belongs to the previously selected filters, if the match is positive, the garment proceeds along the line and is placed by the operator in the appropriate box located at the weighing station.

If the barcode read is not part of the filters, the operator will remove it from the line.

The operation is similar for the second line, which is equipped with a 3 m tunnel with RFID reading antennas. In this case, the operator loads the entire box containing the items to be checked onto the conveyor belt and the RFID reader antennas simultaneously check the content.

LCS and Fabert

“Foresight, that’s what’s needed in entrepreneurship today, a quality that Fabert certainly does not lack, but what can you do without technology? It just couldn’t go on like this, too many mistakes and too many complaints. So the search began for a solution that would be just right for us. And it was thanks to the Internet that we reached LCS. Now we define them partner, not just supplier. As a matter of fact, in the work carried out until now a collaborative and trustful atmosphere has been created, which has led to an excellent result in terms of efficiency and effectiveness.

LCS staff has been very organized and professional and has been able to study for us a solution in line with our needs, adapting the project to our requirements and above all to our customers’ practices”.

Alessia Cassani

Direzione – Fabert S.r.l.

Achieved benefits

The automated system designed and installed by LCS has increased the efficiency of operations and has eliminated errors caused by manual handling of the items to be shipped.

In addition, the solution ensures constant process control and full traceability of individual items, enabling Fabert to fully satisfy the demands of its prestigious customers.

Facts and figures

- High-performance system thanks to RFID reading solution

- Modular and easily adaptable system

- System designed and set up for future expansion with the automation of weighing, strapping and palletizing processes

- The barcode line handles 2000 items/day, in 8 hours